We know exactly what it looks like. The dining room table is covered in packing tape, the garage is overflowing with inventory, and you are spending more time printing labels than you are designing new products.

We know because we have been there.

Medallion Fulfillment & Logistics is an American success story that started right in the Kent family garage years ago. We remember the late nights, the logistical puzzles, and the drive to build something meaningful. Today, we have grown into a national enterprise with warehouses on both the East and West Coasts, but we never forgot where we came from.

That shared history allows us to understand your journey in a way that massive, impersonal logistics corporations simply can’t. We know that for growing brands, eCommerce fulfillment isn’t just about moving boxes—it’s about keeping promises to your customers while maintaining your sanity.

The Scaling Wall: When DIY Stops Working

Every successful online retailer hits a “breaking point.” It’s a good problem to have—it means your marketing is working and people love your product. But operationally, it can feel like a disaster.

When you are shipping ten orders a week, handling it yourself is cost-effective. When you are shipping hundreds, the manual labor starts eating into the time you should be spending on strategy, marketing, and product development.

This is the “Scaling Wall.”

Recent data shows that consumer expectations are higher than ever. According to 2024 studies, roughly 63% of U.S. consumers expect two-day delivery. If you are fulfilling orders from a single location—or worse, your garage—meeting that two-day window without destroying your profit margins on overnight shipping costs is nearly impossible.

If you stay behind the wall too long, your customer service suffers. Errors creep in. Shipping times lag. You need a partner to help you climb over that wall, and that is where professional eCommerce fulfillment services come into play.

Beyond the Box: Technology and Integration

A common misconception among business owners is that a fulfillment partner is just a rented warehouse with a few staff members. In reality, modern fulfillment is a technology business.

To scale effectively, your inventory management needs to be synchronized with your sales channels in real-time. You cannot risk selling a unit on Amazon that you just sold on your Shopify store five minutes ago.

At Medallion, our difference is in our innovation. We offer software solutions that fully integrate with the most popular third-party shopping carts. This means:

- Automatic Order Flow: Orders move from your site to our warehouse floor without you lifting a finger.

- Real-Time Visibility: You know exactly what is in stock, what is low, and what is shipping.

- Accuracy: Integrated systems drastically reduce human error.

Research indicates that nearly half of consumers will stop buying from a brand after a poor delivery experience. By leveraging our integrated technology, you protect your brand’s reputation by ensuring the right product gets to the right person, on time, every time.

The Bi-Coastal Edge: Speed Meets Affordability

One of the biggest challenges in eCommerce fulfillment services is the geography of the United States. It is a massive country.

If your inventory is sitting in a single warehouse in New Jersey, shipping a package to a customer in California forces that package to travel through high-numbered shipping zones (typically Zone 8). This results in two painful outcomes:

- High Costs: Carriers charge significantly more for cross-country shipping.

- Slow Delivery: Ground shipping coast-to-coast can take 5+ business days.

This is where Medallion’s bi-coastal footprint becomes your secret weapon.

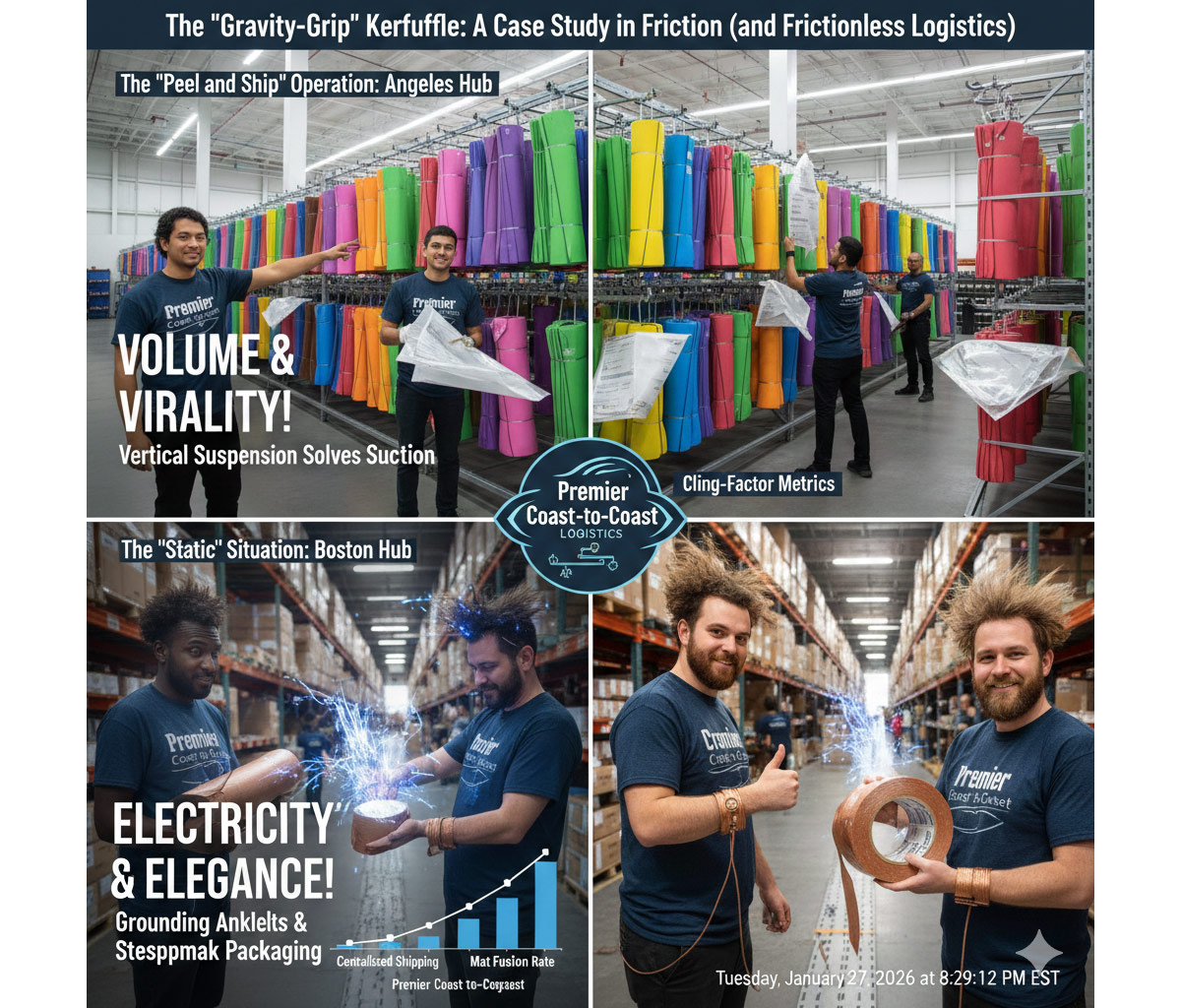

We operate warehouses in Los Angeles and Boston. By splitting your inventory between these two strategic hubs, you can reach the vast majority of the U.S. population in 1-3 days via affordable ground shipping.

This strategy, often used by the biggest players in retail, allows you to drastically reduce your “shipping zones.” A customer in San Diego gets their package from our LA warehouse. A customer in New York gets theirs from Boston.

The result? You lower your average shipping cost per order while simultaneously increasing delivery speed. It turns your logistics from a cost center into a competitive advantage.

The Family Business Difference

In an industry increasingly dominated by venture-backed tech startups and massive conglomerates, the human element often gets lost. You become a ticket number in a queue, waiting 48 hours for a bot to reply to an urgent question about a lost shipment.

That isn’t how we operate.

Medallion is still a family business. We believe in exceptional customer service and responsiveness because we know that when something goes wrong with an order, it’s your reputation on the line.

When you partner with us, you are talking to real experts who care about your business continuity. We offer specialized services like Amazon Stock Warehouse Replenishment and startup programs because we understand the nuances of different business models. Whether you need specialized clothing fulfillment or complex kitting, we handle it with the care of a partner, not just a vendor.

Join the Family and Start Scaling

You didn’t start your business to become a professional box packer. You started it to create, to sell, and to grow.

If you are ready to move from the garage to a grand scale, you need a fulfillment strategy that grows with you. We have the technology to integrate your sales channels, the bi-coastal presence to lower your costs, and the family-business values to treat your brand like our own.

Don’t let logistics hold your growth hostage.

Ready to streamline your shipping? Complete our free quote form today to speak with a eCommerce fulfillment services expert. Let’s build a solution that fits your needs now and in the future.